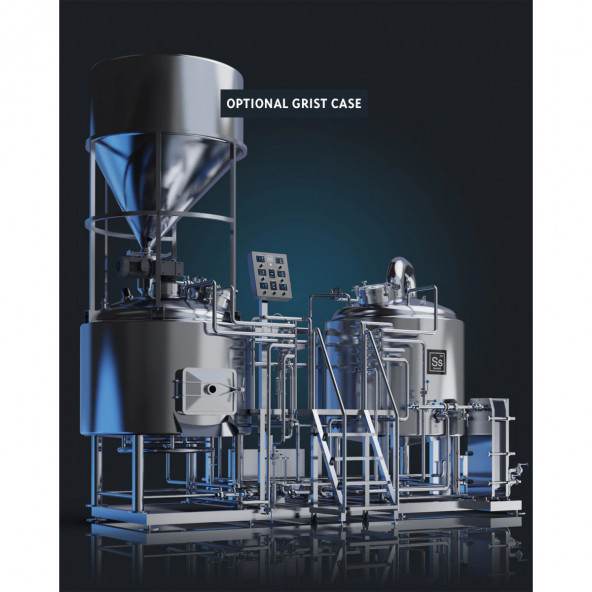

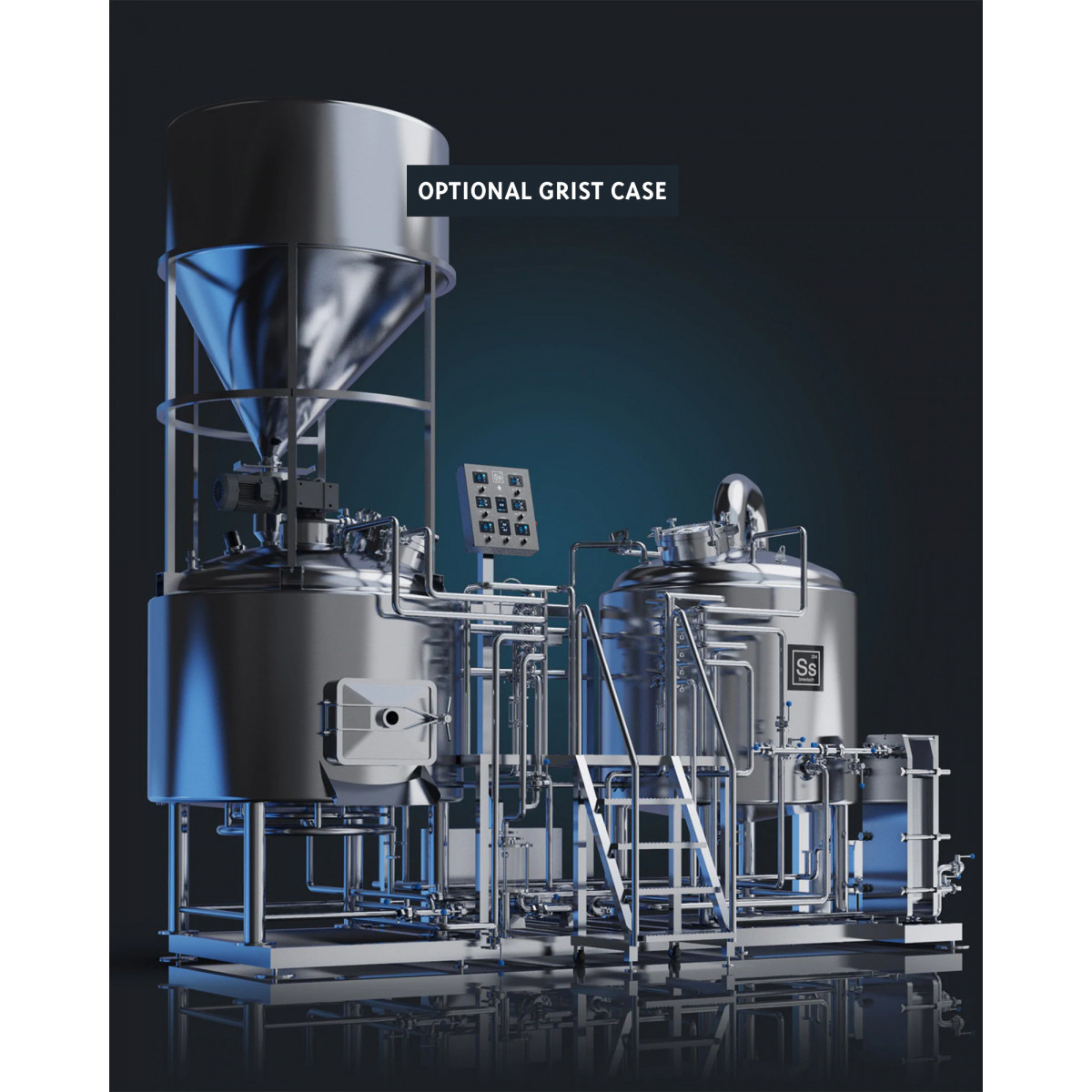

Ss Brewtech™ compact skid-mounted 2 vessel Brewhouse for indirect heating with steam. With plenty of features, designed to make your brew day as easy as possible.

The Ss Brewtech™ Pro line of steam powered brewhouses is designed and built to the highest standards, tolerances, and specifications. These brewhouses offer you precise control of your brew day. Variable frequency drive control of pumps and the rake motor allow for precise adjustment, while the programmable presets enable the brewer to quickly and accurately return to preferred speed settings. Modular screens per vessel make adjusting temperature quick, while also allowing all the necessary information to be available at a glance. The practical manhole, the pneumatic dump switches and the strategically placed electromagnets facilitate maintenance.

A fundamental design element for Ss Brewtech Pro Brewhouses are the brewer-centric controls. The consolidated valve tree is mounted atop the working platform within easy reach of the main control panel. Laser-etched stainless steel butterfly valves allow for precise flow modulation and control without having to continually move up and down the work platform during the brew day. The attention to detail regarding how brewers work enhances both ease of use and safety.

The Dual Pump Architecture designed into every Pro Ss Brewhouse provides a level of flexibility simply not available on single pump systems.

Arguably the most labor-intensive part of any brew day is graining out. All 5 bbl and larger Pro Ss Brewhouses come equipped with a mash rake to reduce striations in your mash, a series of grain-out paddles is integrated into the rake and automatically lock into place and push the grain out of the open door when the rake motor is switched into reverse. Through this process, it is possible to remove nearly all spent grain from the mash tun without manual labor. The remote control box off the platform next to the grain-out door, allows a single operator to grain out with a new level of ease and safety.

All Ss Brewtech Pro Brewhouses are built on a 3 inch square stainless steel Uni-Frame. Freestanding vessels have a propensity to leak over time due to torsion stress on the system's piping. The Uni-Frame holds all pipes and vessels with exacting tolerance, virtually eliminating the risk of a system leak. Additionally, having the brewhouse frame-mounted means most 2 vessel systems ship 100% assembled and require only utilities to be up and running. It's not uncommon for new brewers to brew their first batch within 24 hours of receiving their brewhouse.

Main features:

Kettle

Mash tun

Blending manifold

Wort grant

Heat exchanger

Process equipment

Specifications

| Nominal volume | Gross Volume | Volume to top of rake | Grain bed loading for 6,5% beer |

|

|---|---|---|---|---|

| Mash / lauter tun | 5 bbl / 5.85 hl | 8.3 bbl/ 9.71 hl | 7.1 bbl / 8.3 hl | 161 kg/m² |

| Nominal volume | Gross Volume | Head room | |

|---|---|---|---|

| Boil kettle | 5 bbl / 5.85 hl | 7.9 bbl / 9.25 hl | 35% |

Data sheet

Dimensions (incl. Packaging)