An evolutionary step forward in homebrew technology. Maintaining a stable temperature and cold crashing your beer has never been more efficient.

An evolutionary step forward in homebrew technology. The Unitank 2.0 builds upon the venerable Unitank line by increasing the full body wall thickness from 1.2 to 1.5 mm 304 Stainless Steel. Then Ss Brewtech added a fully laser welded, professional-grade jacketed cooling solution to the already advanced feature set the original Unitank is known for. With up to 50% more cooling surface area, maintaining a stable temperature and cold crashing your beer has never been more efficient.

Features:

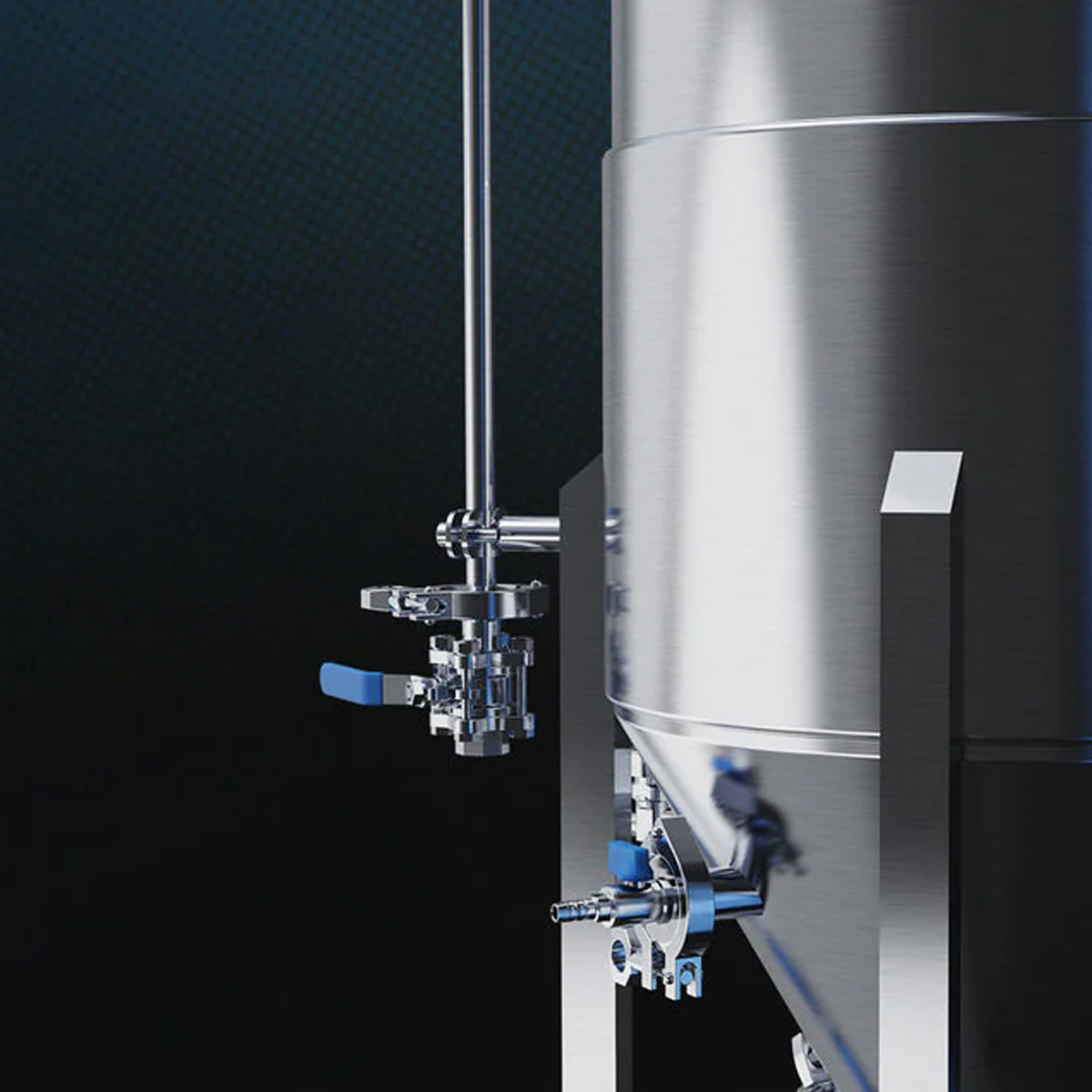

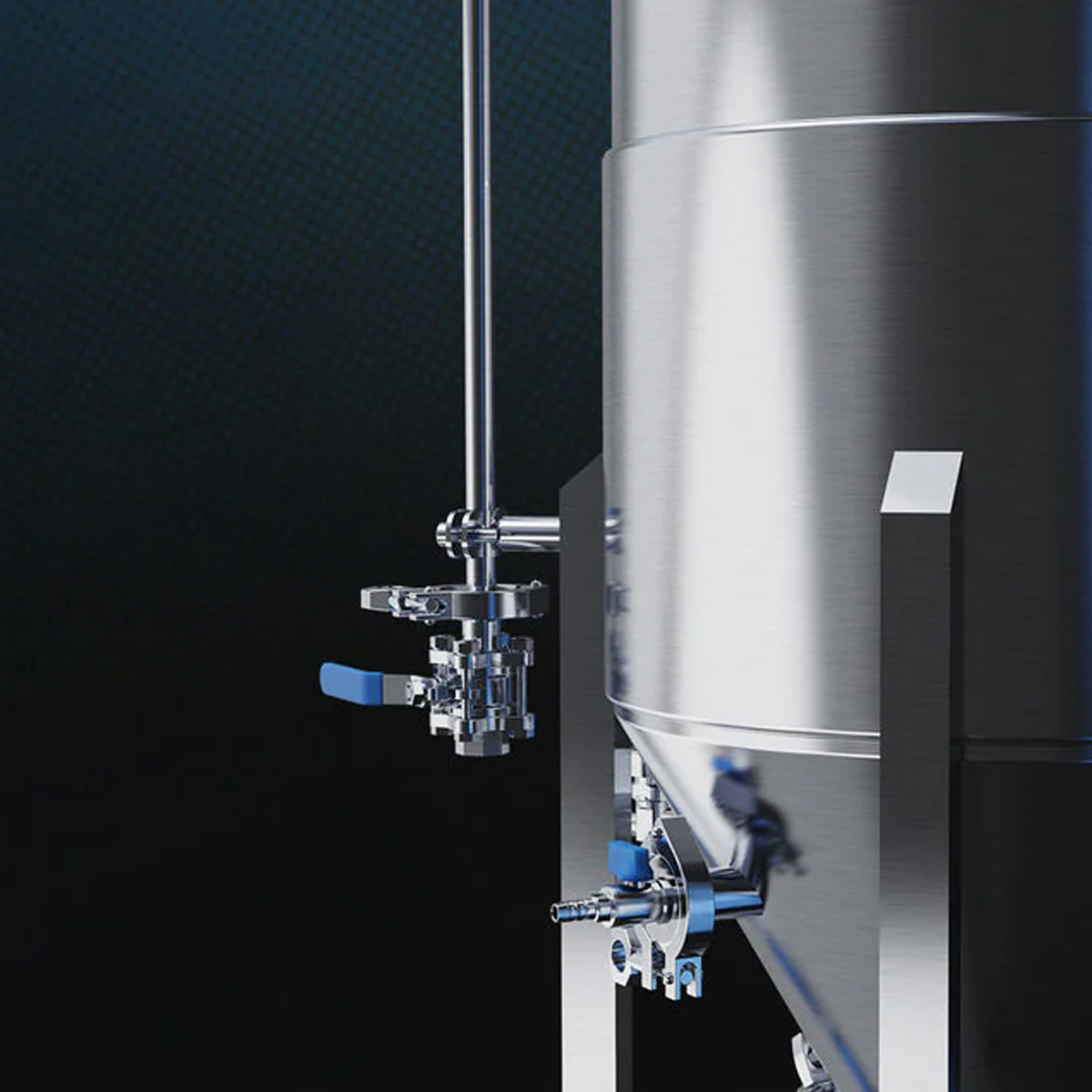

Jacketed Cooling

The benefits of jacketed cooling are numerous, and such engineering has become the standard in Ss Brewtech professional Unitanks for years. With Unitank 2.0, those same benefits are available to the home or nano brewer.

When paired with FTSs Touch and Ss Glycol Chillers, the Unitank 2.0 can provide an uncompromised level of fermentation control. The increased surface area of jacketed cooling allows more precise temp control not seen in the home brew industry. Additionally, the added surface area allows the fermenter to cold crash in even the most challenging environments.

Another benefit of moving to jacketed cooling is that removing the coil makes the cleaning process much more straightforward. When used with the Ss Brewtech CIP ball, cleaning can be performed just as the pros do in craft breweries.

Staggered inlet and outlet ports for the glycol jacket help with even coolant distribution in the jacket. The rear-mounted thermowell cleans up the coolant control wiring for an even more professional setup.

Keyed Racking Arm

Like the Chronical 2.0, the Unitank 2.0 features a version of the new Ss Brewtech racking arm co-molded with the geometry of the valve body and TC gasket; this ingenious design captures the racking arm and prevents it from coming loose. Additionally, the keyed elements of the valve allow the brewer to know precisely what direction the racking arm is facing based on the orientation of the valve on the vessel. What's more, the Unitank valve is the same full pressure-rated valve used on professional Ss Brewtech equipment.

Valves & ports

The Unitank 2.0 continues with all the beloved features of the original Unitank. On top of all the fully welded TC connections and pro features, the Unitank 2.0 allows the brewer to quickly carbonate beer in under 24 hours using the carb stone while precisely monitoring head pressure. After fermenting and carbonating, the brewer can perform a true pressurized and closed transfer to a keg or canning machine significantly reducing the chances of oxidation when compared to open transfers.

Higher pressure limits allow the user to dispense beer directly out of the vessel. Lastly, adding an optional Sspunding Valve to the Unitank gives the brewer the ability to ferment under pressure and gives them the option to use the final few gravity points left of active fermentation to naturally carbonate their beer instead of force carbonate. This feature set and flexibility are why pro brewers use Unitanks in their brewing and packaging processes.

Specifications:

Data sheet

Dimensions (incl. Packaging)